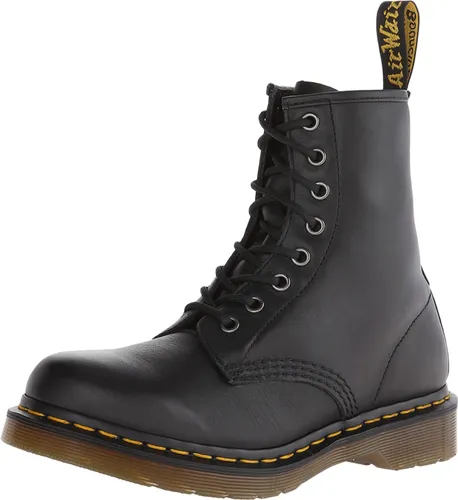

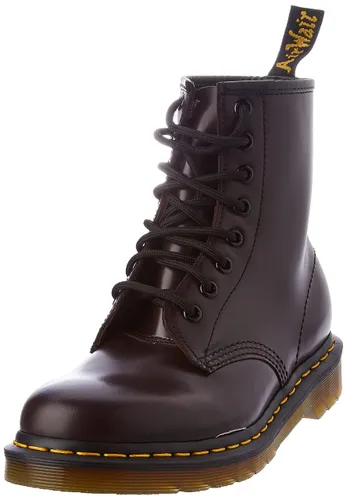

Dr. Martens boots are a wardrobe staple, and every fashionista owns a pair. Every Dr. Martens fan knows the boots will give you blisters. But after you break them in, they feel like cushions for your feet. They may be a bit of a splurge, but they certainly are an investment: a pair of Dr. Martens boots will last a lifetime. That has everything to do with the unique production process of Dr. Martens boots, and we’ll tell you all about it.

How are Dr. Martens boots made?

You may think a pair of Dr. Martens boots is produced just like any other boot, but nothing could be further from the truth. There are so many things we don’t know about Dr. Martens, but the brand is very proud of their exceptional production process. Step by step we’ll explain how your Dr. Martens boots are produced.

# 1 Injection Melting Machine

The production of a Dr. Martens boot starts with a PVC-sole. To get the right shape of the sole, the company uses a unique cast machine. Fluid PVC is injected into a mould and then this is clamped together under warm conditions, which causes the substance to melt together. Because PVC is oil and acid resistant, and the sole softens due to wear, the risk of cracking and splitting is reduced.

#2 Clicking room

The next step takes place in the Clicking room. Based on a standard mould, all parts of the upper are cut out of leather. As the room’s name already implies: all shapes are clicked out of the leather using a hydraulic press machine. After cutting all leather parts, the thickness of the leather is checked and the size is noted. The size is noted with a metal relief and foils.

#3 Closing room

The production of a Dr. Martens boot then continues in the Closing Room, where all loose leather parts are sewn together. You may think all machines in the Closing Room are the same, but in fact, every machine has its own function. The most important machine is the ‘Puritan Machine’. The Puritan is responsible for the famous look & feel of Dr. Martens.

Before the Dr. Martens boot leaves the Closing Room, eyelets are stamped in the leather and the nose of the boot is firmed with a sort of toe protector.

#4 Lasting Track Room

In the Lasting Track Room, the leather upper is moulded to a foot’s shape. First, a mould is put in the leather and then the leather is adjusted to create the foot’s shape. Before the shoe is attached to the sole, the excess leather is cut away.

After this, they add the yellow thread Dr. Martens is known for. The yellow thread attaches a rim of PVC to the leather upper. According to Dr. Martens this concept is unique since most shoe manufacturers use a leather rim. Because Dr. Martens uses PVC, the rim and PVC sole are melted together to make it an ensemble. During this process, no adhesive is used to make the Dr. Martens boot indestructible.

The last step in the Last Tracking Room is grinding all excess PVC. The grinder has a grooved edge which makes small lines on the sole. Again, this is a typical feature of Dr. Martens boots.

#5 Shoe Room

Before the Dr. Martens boot is ready for selling, it has to go to the Shoe Room. Here the shoes are checked, polished, and the laces are threaded. Once the Dr. Martens boots are approved, they are placed in a box and ready for disposal.

Production of Dr. Martens boots

During the Sixties of the twentieth century, Dr. Martens was born out of frustration with the stiff soles worker shoes had at that time. Dr. Martens came up with an alternative and created AirWair: a sole filled with air. Up to today, AirWair is still part of Dr. Martens boots, but the brand still thinks that quality, simplicity and solidity are essential as well. These characteristics are central to the production of Dr. Martens boots.

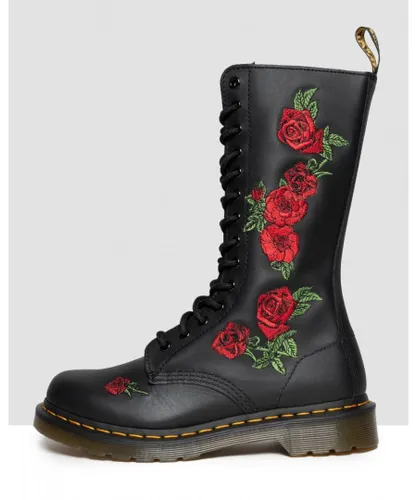

Until 2003 Dr. Martens produced all their shoes in the Cobbs Lane factory in Wallaston. Since then, the boot has become extremely popular, and the production was moved to Asia. The customized Dr. Martens editions are still made in the 120 years old factory in Wallaston. The video below explains how Dr. Martens boots are made in this factory.